Concrete Batching Plant

Concrete Batching Plant

A concrete plant, is otherwise called as batch plant or batching plant or a concrete batching plant. It is equipped to combine various ingredients to form concrete. Some of these inputs are water, air, admixtures, sand, aggregate (rocks, gravel, etc.), fly ash, silica fume, slag, and cement. There are two types of concrete plants: Dry mix plants and Wet mix plants. It is used to lay roads, build heavy buildings etc,.

Salient Features

- Robust Structure

- Large platforms for ease of maintenance

- Modular design Providing Flexibility of adopt different layout requirements

- Design for Ready –Mix producers ,Road ,Dam Projects, Contractors and Special Applications

- Available in various capacities ranging from 30 cubic meters to 240 cubic per hour.

Following are the capacities available

- 30 mᵌ/hr

- 45 mᵌ/hr

- 90 mᵌ/hr

- 60 mᵌ/hr

- 75 mᵌ/hr

- 120 mᵌ /hr

- 240 mᵌ /hr

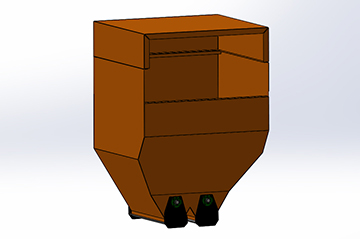

Aggregate Storage Bins

Bin supporting Structure is made of Parallel Flange H Beam of adequate size to store required volumes of aggregates through corrugated Bin extensions. Greater batching accuracy and optimum production efficiency is achieved through twin gates for each bin.

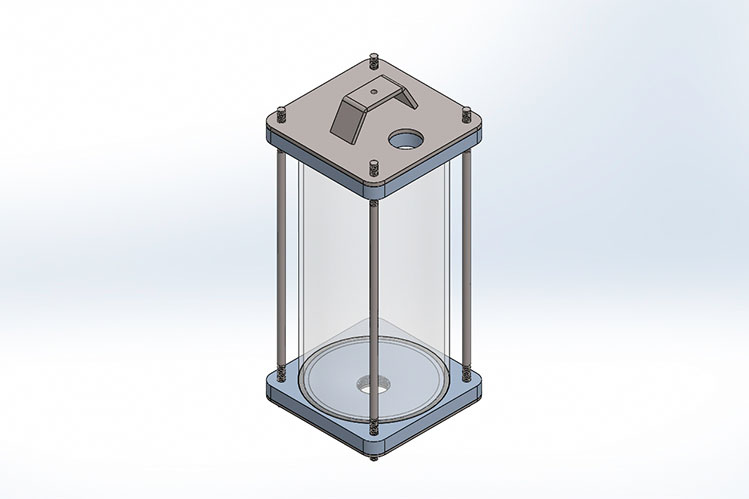

Weighing Conveyor

This Belt Conveyor suspended on shear beam type load cells below the aggregate gates to weigh batch the aggregates and is driven by Torque Arm Mounted Hollow output shaft geared motor. External and Internal Belt scrapers are provided for trouble free weigh batching and the skirt board with flow adjuster ensures smooth and effective transport of aggregates to the transfer conveyor.

Inclined Transfer Conveyor

This conveyor transfers the weighed aggregate discharged from weigh belt conveyor to the Holding Hopper placed on top of the Mixer. This conveyor is supplied with Chevron belt and back stop gear motor.

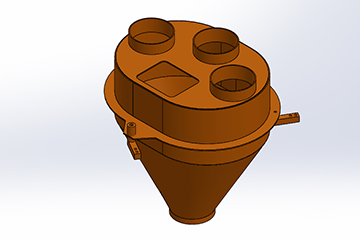

Holding Hopper

This holding hopper facilitates storing of weighed aggregate Transferred by the inclined conveyor from the weight beltconveyor .The aggregate gate is discharged to the mixer by a Pneumatic gate

Cement Weigh Hopper

This cement weigh hopper is located on top of mixer and suspended on load cells fixed to a rigid structure above the mixer platform. An electric vibrator assists the flow of cement to the mixer by gravity.

Water Weigh Hopper

This water hopper is located on top of mixer and Suspended on load cells fixed to a rigid structure Above the mixer platform.

Admixture Pumping, Weighing and Dispensing System

This admixture unit is located on top of mixer and suspended on load cells fixed to a rigid structure above the platform. This admixture system consists of gear pump and pneumatic dispensing system

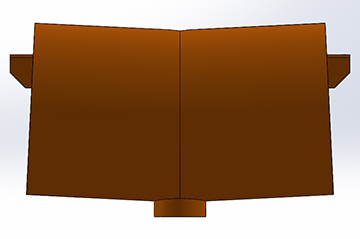

Twin Shaft Mixer

The twin shaft mixer offers the most advanced mixing solution, capable of handling from high to zero slump concrete. The twin shaft mixer consists of two horizontal shafts with arms and paddles moving in the opposite direction, which ensures optimum mixing. The mixer consists of hydraulic discharge gate to discharge the mix material into transit mixer or dumper.

Control Panel

Fully automatic and air conditioned control unit that contains Controls for various operations like power control, Sequence Control, distribution power control, automatic batching control. The Control unit is totally pre wired. It also includes very user Friendly software with SCADA option.